WHO WE ARE

Krizen Group, founded in 1996, is a trusted forging partner with 30+ years of experience across automotive, machinery, and agriculture sectors.

We deliver end-to-end solutions with precision-engineered components built for long-term performance and reliability.

Our vision

We are committed to fulfil this vision with a mindset of GROWTH

>Going global

>Optimistic

>Honest

>Working together

>Realistic solutions

>T3 (Time, Technology & Talent)

>Going global

>Optimistic

>Honest

>Working together

>Realistic solutions

>T3 (Time, Technology & Talent)

Our mission

By collaborating with right technology partners and market leaders to become world class supplier in the field of forging.

Honestly, we don't settle for anything less than excellence and innovation through committed team work.

global reach

+

offices worldwide

local expertise

+

employees

What We Do

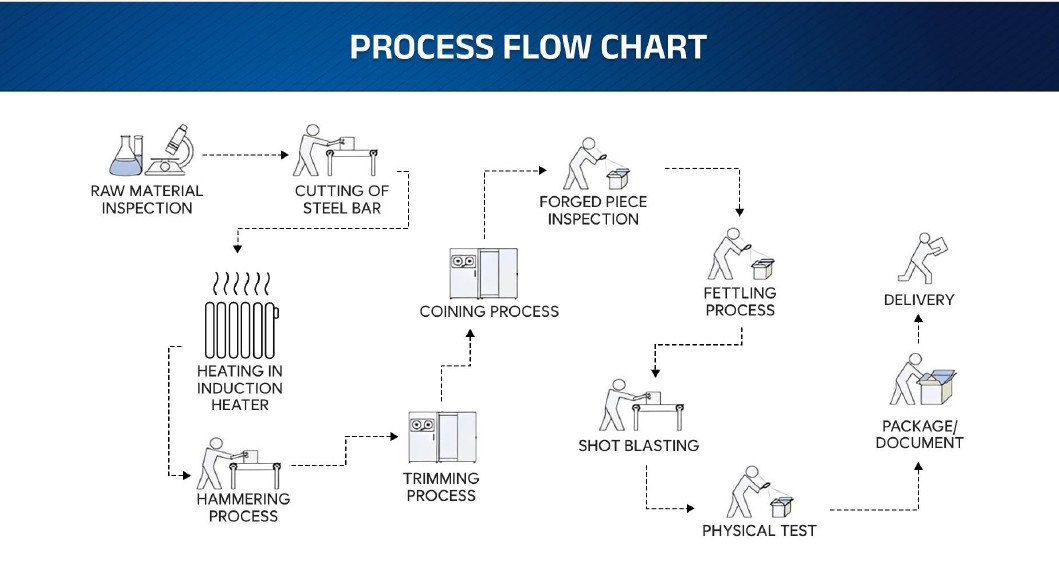

We Support Our Customers from Design to Delivery

Design to Final Delivery

We are not only a contract manufacturer of parts; we support our customers from the design stage through to final delivery.

Engineering Best Practices

By working with a wide range of components and product designs, we help customers define design best practices and optimize product development.

Product Development Support

We support our customers step by step in developing the right products designed for manufacturing, performance, and cost efficiency.

Machining & Heat Treatment

Our in-house machining facility performs final machining to required tolerances, and our heat treatment partners ensure the desired material properties for tailor-made solutions.

Awesome Services

We are a dynamic company with broad industry expertise. Our extensive experience has established us as a trusted partner in the automotive, machinery, and agriculture sectors.

While these are our core industries, we are not limited to them. Our in-house quality control laboratory, state-of-the-art machining shop, and forging and engineering capabilities also allow us to deliver high-quality products for a wide range of industrial applications.

AUTOMOTIVE

In the automotive industry, forging is selected for high-stress components because it produces parts that are significantly stronger and lighter than cast alternatives, directly improving vehicle safety and fuel efficiency.

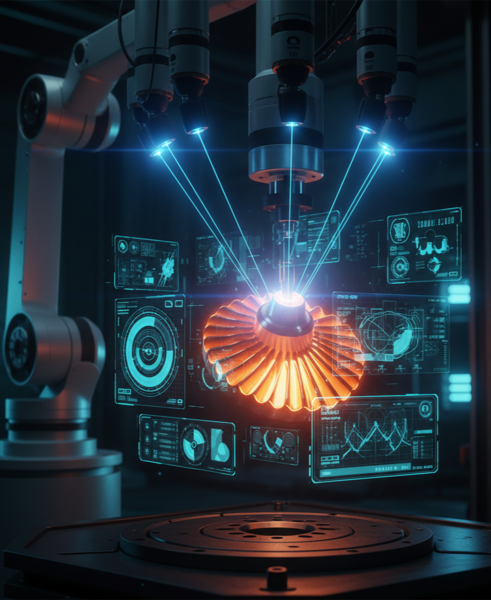

AEROSPACE

In the aerospace industry, forging is the preferred manufacturing process because it provides unmatched structural integrity and strength for mission-critical parts like turbine blades and landing gear.

AGRICULTURE

In the agricultural industry, forging is chosen because it creates components with extreme durability and impact resistance, allowing machinery to survive the relentless stress of tilling rocky soil and harvesting under high torque.

CONSTRUCTION

In the construction industry, forging is the preferred method for manufacturing heavy-duty components because it produces parts with exceptional load-bearing capacity and shock resistance, ensuring that machinery can withstand the brutal forces of excavation and structural support.

DEFENCE

In the defense industry, forging is the standard for mission-critical hardware because it ensures unfailing reliability and extreme impact resistance under combat conditions.

ELECTRICAL TRANSMISSION

In the electrical transmission industry, forging is chosen because it produces high-strength hardware that can withstand massive mechanical tension and extreme weather without failing, ensuring the continuous flow of power across the grid.

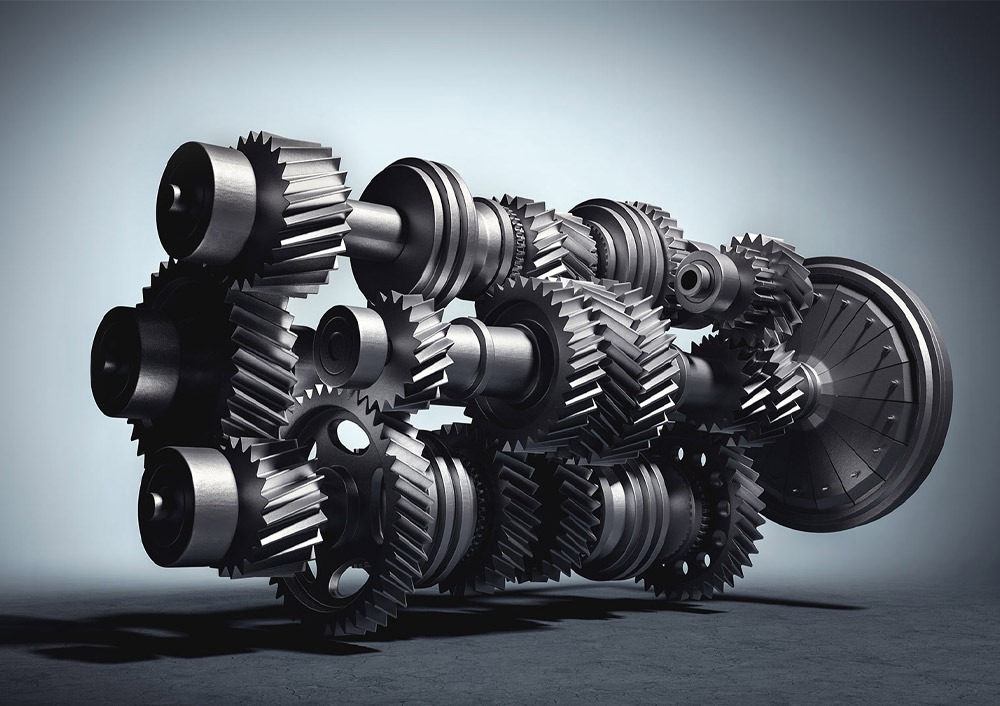

GEAR & TRANSIMISSION

In the gear and transmission industry, forging is the gold standard for manufacturing because it creates parts with extreme torque capacity and long-term fatigue resistance, ensuring that power is transferred smoothly without the risk of gear tooth failure.

HEAVY ENGINEERING

In the heavy engineering sector, forging is the preferred manufacturing choice because it produces massive components with unparalleled structural integrity and high load-bearing capacity, ensuring that industrial machinery can operate under extreme stress for decades.

MARINE

In the marine industry, forging is the preferred manufacturing process for critical components because it ensures maximum resistance to saltwater corrosion and extreme mechanical stress, protecting vessels against the unpredictable power of the open sea.

OIL & NATURAL GAS

In the oil and natural gas industry, forging is the essential choice for manufacturing because it produces components capable of withstanding extreme internal pressures and highly corrosive environments without the risk of catastrophic leaks.

POWER GENERATION

In the power generation industry, forging is the preferred manufacturing process because it provides extreme fatigue resistance and structural reliability, ensuring that critical rotating components can operate continuously under intense heat and pressure for decades.

RAILWAY

In the railway industry, forging is the preferred manufacturing process because it produces components with unparalleled toughness and fatigue resistance, ensuring that trains can safely carry massive loads at high speeds over thousands of miles.

TEXTILE

In the textile industry, forging is chosen for high-speed machinery components because it provides the vibration resistance and surface density necessary to maintain precision during continuous, high-volume production.

+

completed

projects

projects

+

projects in

development

development

b+

total projects

cost

cost

m+

square feet

of property

of property

contact us

Let’s Work Together

We’d love to share more with you, please complete this form and

our dedicated team will get back to you shortly.

our dedicated team will get back to you shortly.

Call Us

+91 76000 73516

+91 97245 25336

+91 97245 25336

Our Email Us

krizentechnoforge@gmail.com

Location

Plot no. 2C, Opposite Uma Jug, OPP. Street of lshwar Weigh Bridge, Verval-Padavla Road PAdavla-3600024 Rajkot-360005 Gujarat.

Choose Options

RTL Version

- RTL Version

- LTR Version

Want Sticky Header

- No

- Yes

Dark Verion

- Yes

- No

You will find much more options for colors and styling in admin panel. This color picker is used only for demonstation purposes.

buy now

buy now